machining surface finish ra

As already mentioned there are three basic. The standard roughness for CNC machined parts is Ra 32 microns but you can do as fine as for example 02 microns on a CNC machine but it might take 10 times longer and.

5 Grinding Considerations For Improving Surface Finish Norton Abrasives

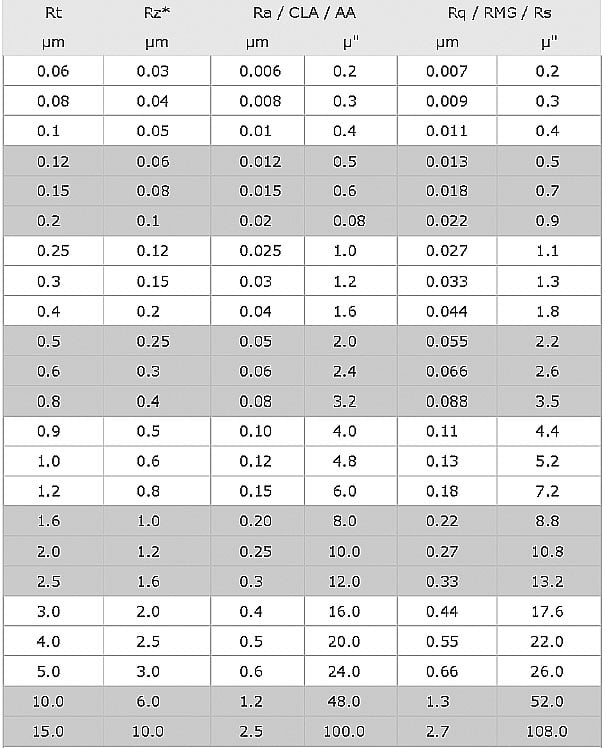

This table will help you understand the impact of the machining process on the surface finish.

. Determining the surface roughness is the first step that should occur after plastic parts are machined. Ra surface finish chart shows the arithmetic average of surface heights that have been measured across a surface. At Xometry Europe we offer four surface roughness levels that are also the values typically specified for CNC Machining applications.

The average synchronous polishing time is 314 times less than single-spindle machine tool the surface roughness of the polished blade can satisfy Rale 04 mu m. Surface finishes may be increased to 16 08 to. Minorly visible tool marks with a standard surface roughness Ra of 32μm.

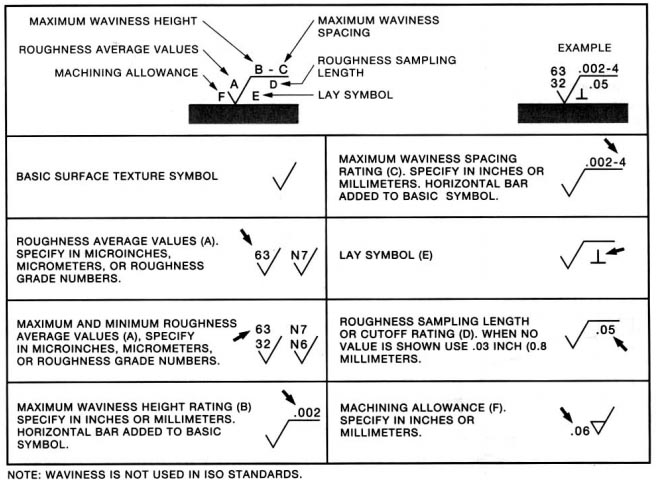

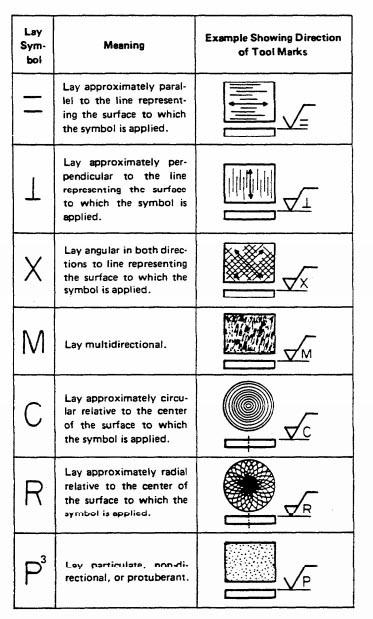

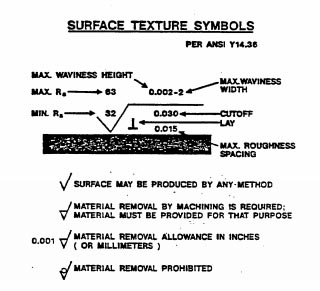

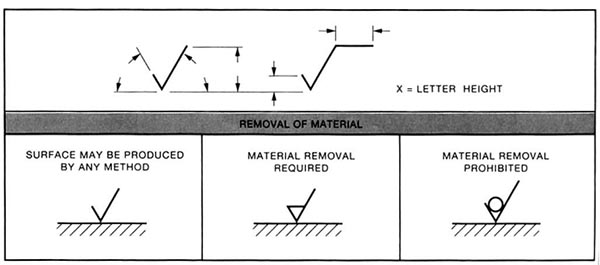

Knowing what manufacturing process can produce surface finishes that desired on a surface can be an. Surface Finish Units From RA To Rz. When you see a machining surface finish chart you may find it difficult to understand the abbreviations.

The chart lists the name of the finish the roughness in microns and the applications. It is difficult to measure surface roughness without. As you know various acronyms are used in machining surface finish.

The value of surface roughness therefore is paramount and extra precaution should be taken while performing CNC machining. This is done through measurements by using a. Surface Roughness Produced by Different Manufacturing Process.

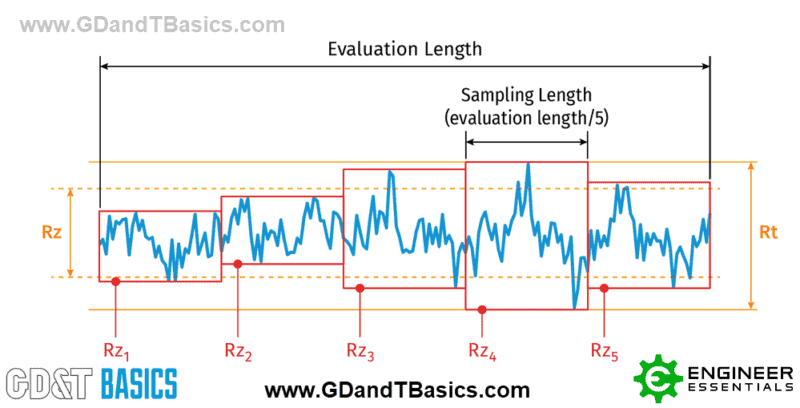

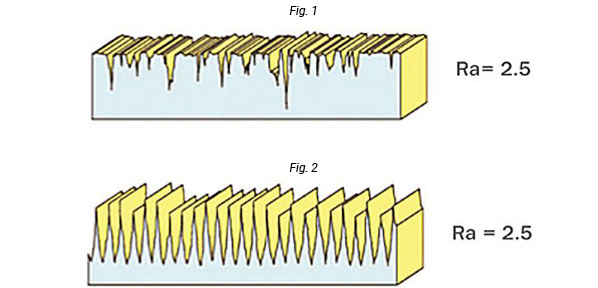

In the end a chart as shown above has to be analyzed and yield a single number that represents the surface finish. Unfortunately there are several different units of measurement in use and it. It is considered to be the most acceptable method of measuring surface roughness.

The value of surface roughness of the machined part is not. Surface finish also known as surface texture or surface topography is the nature of a surface as defined by the three characteristics of lay surface roughness and waviness. The plastic surface finish chart is a guide to the various finishes that can be applied to plastic parts.

Indicative Surface Roughness Comparisons. The numeric parameter Ra. According to doctor blades manufacturer Swedevs website Ra is the arithmetical average value of all absolute distances of the roughness profile from the center line within the.

Yide Casting is a leading iron foundry provide both casting service and machining service equipped. The surface finish comparator for milling turning reaming and grinding. Ra Average Roughness.

Surface Roughness Conversion Chart Tables

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Cnc Machining Surface Finishes Introductions Cnc Surface Roughness Texture Topology Finishing

Shop Tips 293 Surface Roughness Finish 1 Of 2 Tubalcain Youtube

The Basics Of Surface Finish Gd T Basics

On Machine Surface Finish Measurement Metrology And Quality News Online Magazine

Beyond Ra Why Surface Finish Matters In Seal Performance Fluid Power Journal

The Difference Between Ra And Rz Production Machining

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Complete Surface Finish Chart Symbols Roughness Conversion Tables

What Is Surface Finish Units Symbols Chart Engineering Choice

Our Surface Finishes Standards For Cnc Machining Hubs

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Roughness Conversion Chart Surface Finish Importand Tips And Tricks Limits And Tolerance Youtube

Measured And The Predicted Values Of Surface Roughness Ra And Rz And Download Table

Selecting Right Surface Roughness For Cnc Machining Xometry Europe

Image Of Surface Finish Under Microscope A Surface With Ra 20 Nm B Download Scientific Diagram